EOT CRANE-SINGLE GIRDER (MSGEC)

Our all manufactured products are economical, simple, safe to use and efficient. We are also having to manufacture and modify our products as per demand and requirements of clients. These Single Girder Cranes are widely used in different foundries, chemical industries, steel industries, machine shops all across India. Our products are designed to reduce cost, minimum crane structural weight.

Single Girder Cranes are designed to cover a wide range of modern industrial demands, providing excellent value for money with no compromise on performance. Our single girder crane has reduced wheel loads, saving costs on new support structures and increased lifting capacities on existing structures.

We offer various crane beam to end carriage constructions to ensure optimum use of headroom available. Hoists are offered as standard in low headroom format running on the bottom flange of the beam. Hoist design ensures maximum cross bridge hook stroke with minimum side clearances.

E.O.T. CRANES Designed and

developed to bear heavy loads for

longer time spans.

our range of E.O.T Cranes is a perfect

solution which is advantageous over

the conventional cranes.

Our E.O.T. Cranes are provided as per

client specification and requirement.

UNDER SLUNG TYPE E.O.T. CRANES that are also known as transfer cranes and are used to transfer loads form one bay to another. We develop and supply modern technology made Single Girder EOT Cranes, catering to suit our customers’ requirements. Proper study and analysis is done which as a result guarantees best design, minimum crane structural weight, wheel loads headroom and clearances.

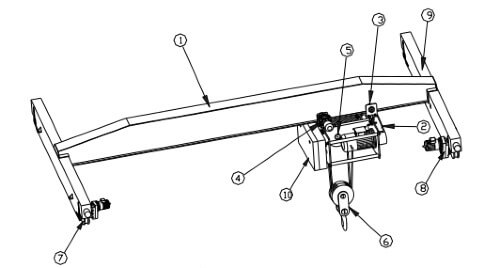

| 1 | Bridge Girder |

|---|---|

| 2 | Hoist Mechanism |

| 3 | CT Wheel |

| 4 | CT Gear Box |

| 5 | Equalising Assembly |

| 6 | LT wheel mechanism |

|---|---|

| 7 | Bottom Block Assembly |

| 8 | LT Gear Box |

| 9 | LT End Carriage |

| 10 | Control Panel |

OPERATION OF CRANES:

Although adequate care has been taken while designing the crane and various safety Features provided, the overall safety and maintenance of cranes depends to a large extent on the skill of the operator.

A trained and efficient operator could contribute to a large extent in reducing maintenance cost and prolong the life of the crane by skilful manipulation of the controls allowing the motors to accelerate gradually to avoid heavy impacts and prevent high current draw The operator shall avoid swinging the loads and shall coase the crane to stop rather than causing sudden stopping of the motor and hard braking which result in Skidding of brakes.

Therefore, it is absolutely essential that operator is given proper training in handing the crane and is duly certified by a qualified person before he is permitted to handle the crane independently t may be ensured that no one should be in the cab with the crane operator except when under training or on maintenance duties Likewise, no person shall be on the bridge walkway or on the trolley during normal operation. 12 Operating Procedure

HOIST MECHANISM:

The rope drums are fabricated out of seamless tubes or steel plates conforming IS 2062 & driven by a motor, through totally enclosed oil immersed Gear box with helical teeth, flexible gear connection. The lower block consists of encased rope sheaves of adequate dimensions as recommended by the relevant standards.

CROSS TRAVERSE MECHANISM:

Wheel driven by electric motor through totally enclosed, oil immersed gear box, floating shafts, flexible geared coupling drive for input & output connections.

LONG TRAVERSE MECHANISM:

Single / Twin drive by electric motor through horizontal / vertical gear box. Flexible geared coupling drive of input & output connections.

BRAKES:

Fail safe, Electromagnetic Disc / Shoe or Electro Hydraulic Thrustor Brakes of 150% torque or more are fitted on shaft extensions in all motion. For heavy duty craces, a second brake can be mounted to ensure fail safe operations.

CRANE CONTROL:

From floor through Pendant Push Buttons / Open cabin / totally enclosed cabin, operation at 110/24V, Electrical switch gear mounted inside dust proof control panels with suitable access for maintenance.

FEATURES:

Single Girder Cranes use Standard components and controls to ensure reliability.

Rapid access to spare parts of the cranes for minimum impact to customers.

Reduced scheduled maintenance and emergency downtime.

Designs conform to IS 807, IS 3177 or IS 4137.

Optimum design ensuring minimum dead weight, wheel load, head room and clearances, reducing building costs.

Forged wheels moved on spherical roller bearings resulting in trouble free service for cross and long travel.

Wide range of lifts.

Wide range of speeds for hoisting, micro-hoisting and long travel to suit every operational requirement.

Hobbed gears from high carbon alloy steels for long trouble free service.

Standardised unit sub-assemblies are used at complete range ensuring spares supply from stocks.

Quick deliveries and prompt after sales service.

V.V.F Drive used in Double Speed Cranes.

Easily adjustable limit-switches.

End carriages fabricated from rolled steel with internal diaphragms for high tensional resistance.

SPECIFICATIONS:

Span: 7.5 ~ 40 m

Rated Loading Capacity: 1 ~ 20 tons

Rated Lifting Moment: 10 KN ~ 200 KN